Introduction

Scotch marine boilers have long been the unsung heroes of maritime engineering, silently powering vessels across oceans and waterways. Despite their crucial role, these boilers often operate unnoticed by passengers and crew alike.

In this article, we delve into the intricacies of Scotch marine boilers, exploring their history, functionality, advantages, and significance in modern maritime propulsion systems.

A Brief History

The roots of Scotch marine boilers can be traced back to the early 19th century, a time when steam propulsion was revolutionizing maritime transportation. Developed by engineer James Watt, the Scotch boiler was designed to address the limitations of earlier boiler designs.

Its distinctive cylindrical shape with two or more large cylindrical furnaces provided increased heating surface area and improved efficiency, making it ideal for marine applications.

Functionality and Design

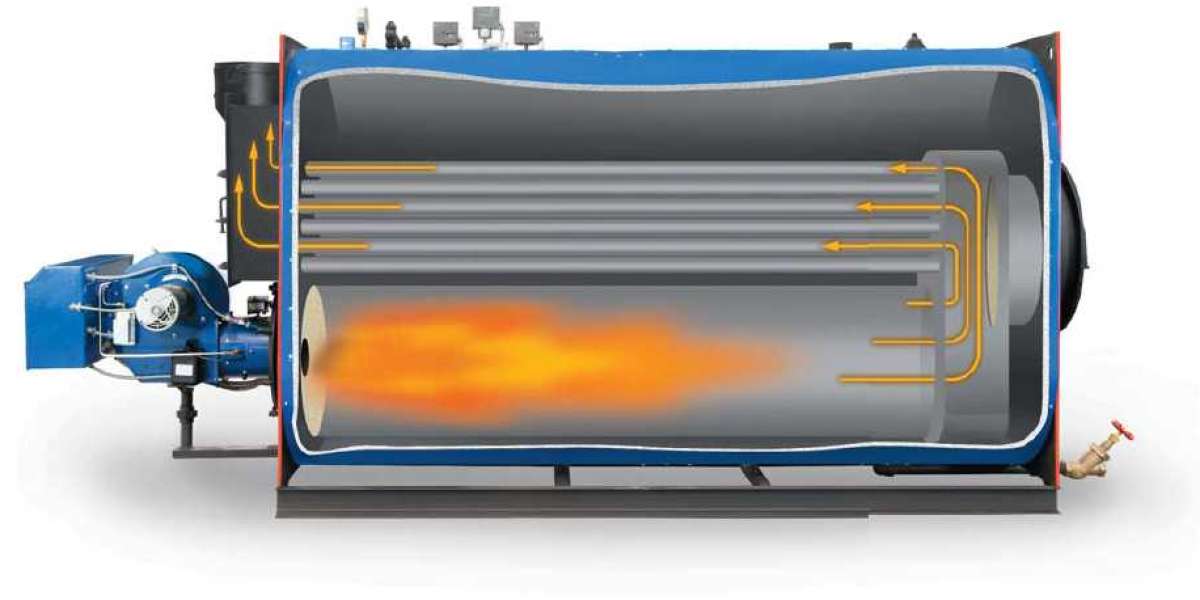

At the heart of a Scotch marine boiler lies its cylindrical shell, which houses one or more combustion chambers or furnaces. These furnaces are surrounded by water, with tubes running through them to facilitate the transfer of heat.

As fuel is burned within the furnace, the heat generated is absorbed by the water, producing steam. The steam is then directed to the engine, where it is used to drive turbines or piston engines, propelling the vessel forward.

Advantages of Scotch Marine Boilers

One of the key advantages of Scotch marine boilers is their compact design, which allows for efficient use of space within the confines of a ship's hull. Their cylindrical shape and horizontal orientation also contribute to their stability and ease of installation.

Additionally, Scotch boilers are known for their robust construction, which enhances durability and reliability, essential qualities for marine applications where safety is paramount.

Efficiency and Performance

Scotch marine boilers are renowned for their high thermal efficiency, thanks to their large heating surface area and effective combustion chamber design. This efficiency translates to lower fuel consumption and reduced emissions, making them environmentally friendly choices for marine propulsion.

Furthermore, their ability to quickly generate steam and maintain steady pressure ensures smooth and reliable operation, crucial for long voyages across unpredictable seas.

Significance in Modern Maritime Industry

Despite advances in propulsion technology, Scotch marine boilers remain widely used in various types of vessels, including cargo ships, passenger ferries, and naval vessels. Their proven track record of reliability and efficiency makes them a preferred choice for many shipbuilders and operators.

Moreover, ongoing innovations, such as the integration of digital monitoring and control systems, continue to enhance their performance and safety standards, ensuring their continued relevance in the modern maritime industry.

Maintenance and Safety Considerations

Proper maintenance is essential for ensuring the safe and efficient operation of Scotch marine boilers. Regular inspections, cleaning, and testing help identify and address potential issues before they escalate, minimizing the risk of accidents or downtime.

Additionally, adherence to strict safety protocols and regulations is paramount, with trained personnel overseeing boiler operation and maintenance procedures at all times.

Conclusion

Scotch marine boilers may not capture the limelight like other components of a ship's propulsion system, but their importance cannot be overstated.

As the backbone of marine propulsion systems, these boilers continue to play a vital role in powering vessels worldwide, enabling safe, efficient, and reliable transportation across the seas.

With ongoing advancements in technology and a commitment to safety and sustainability, Scotch marine boilers are poised to remain indispensable assets in the maritime industry for years to come.